Ceramic Bearings Better Than Steel

Full ceramic bearings have races and balls that are made entirely of ceramic material and are superior to common steel bearings in many ways.

Ceramic bearings better than steel. Ceramic bearings vs steel bearings ceramic materials offer superior corrosion and heat resistance higher dimensional stability and lower density which facilitates high speed. As ceramic bearings do not. It is required to prevent bearing seizure when it warms up and expands. This reduces friction by up to 40 as well as energy loss allowing your equipment to run more efficiently with ceramic ball bearings.

Campagnolo chooses to put ceramic bearings in all of its wheelsets from mid range upwards. The ceramic balls when manufactured by a top quality bearing manufacturer are rounder lighter and smoother than steel balls. The bearing clearance is a measurement given to the small gap between the inner race outer race and balls. Another common difference in bearing construction is the cage type.

It takes weeks for a kogel ball to sit in a tumbler and be perfectly polished. Ceramics are inert whereas metals are reactive making ceramics resistant to corrosive materials such as seawater and many chemicals including acids and alkalis. Ceramic bearings exist to help manage heat in high rpm applications. A ceramic bearing is also harder than steel bearings up to 30 which improves durability and they also don t rust so less maintenance should be required.

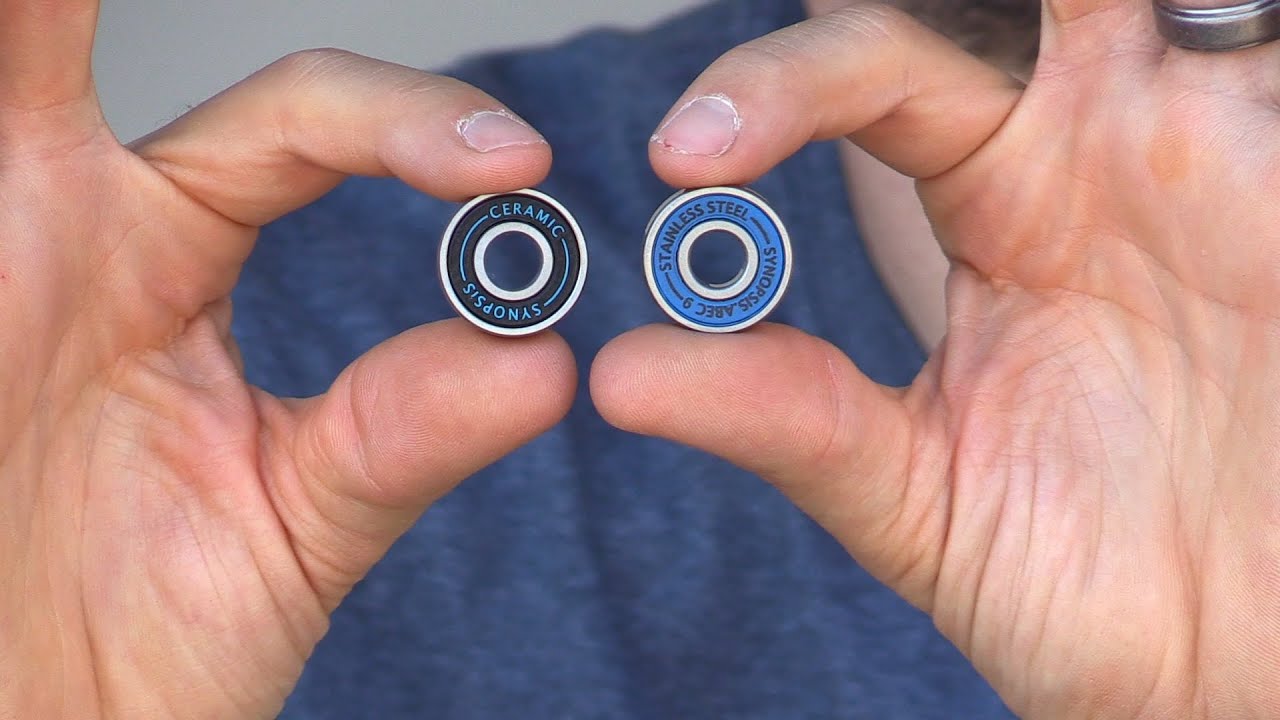

The first thing that strikes the eye when looking at bicycle bearings is the difference in price between steel bearings and hybrid ceramic bearings. They are more corrosion resistant harder and last longer in everyday use. Ceramic is the perfect material for any application seeking to achieve higher rpm s reduce overall weight or for extremely harsh environments where high temperatures and corrosive substances are present. Most sealed ceramic bearings are actually hybrid ceramic bearings which combine a steel race with ceramic ball bearings.

This is mostly due to the additional time spent to perfect a quality ceramic ball. On ceramic bearings this is usually a c3 clearance whilst on steel it s usually cn.