Ceramic Binder Composition

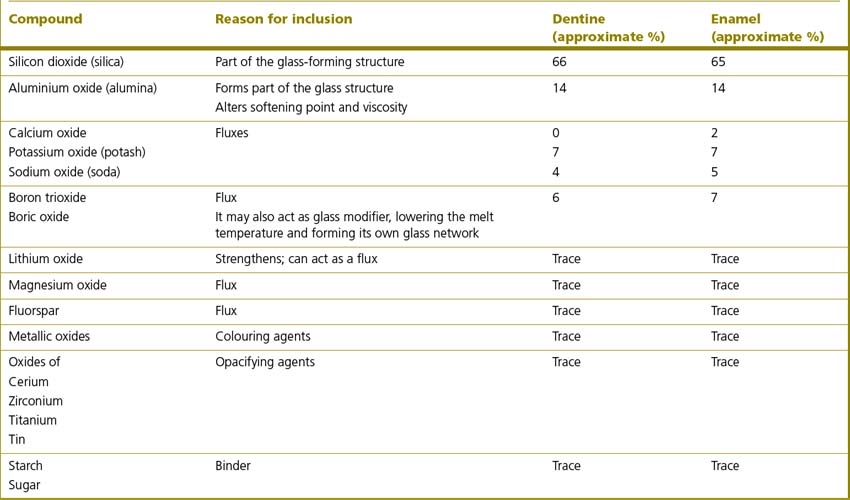

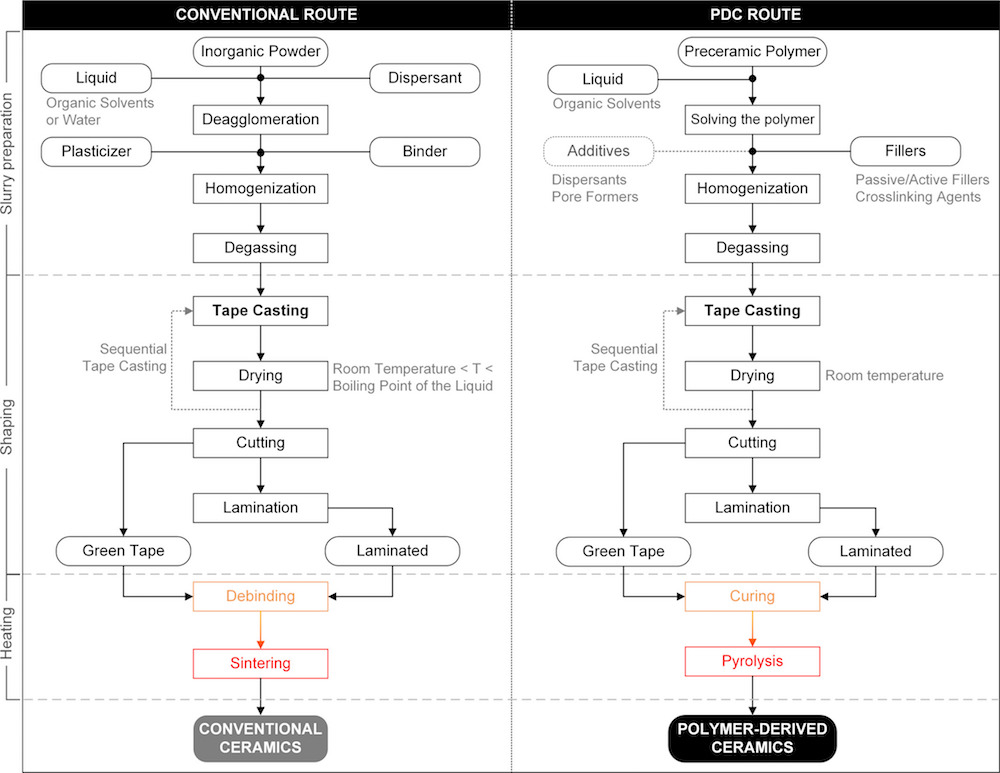

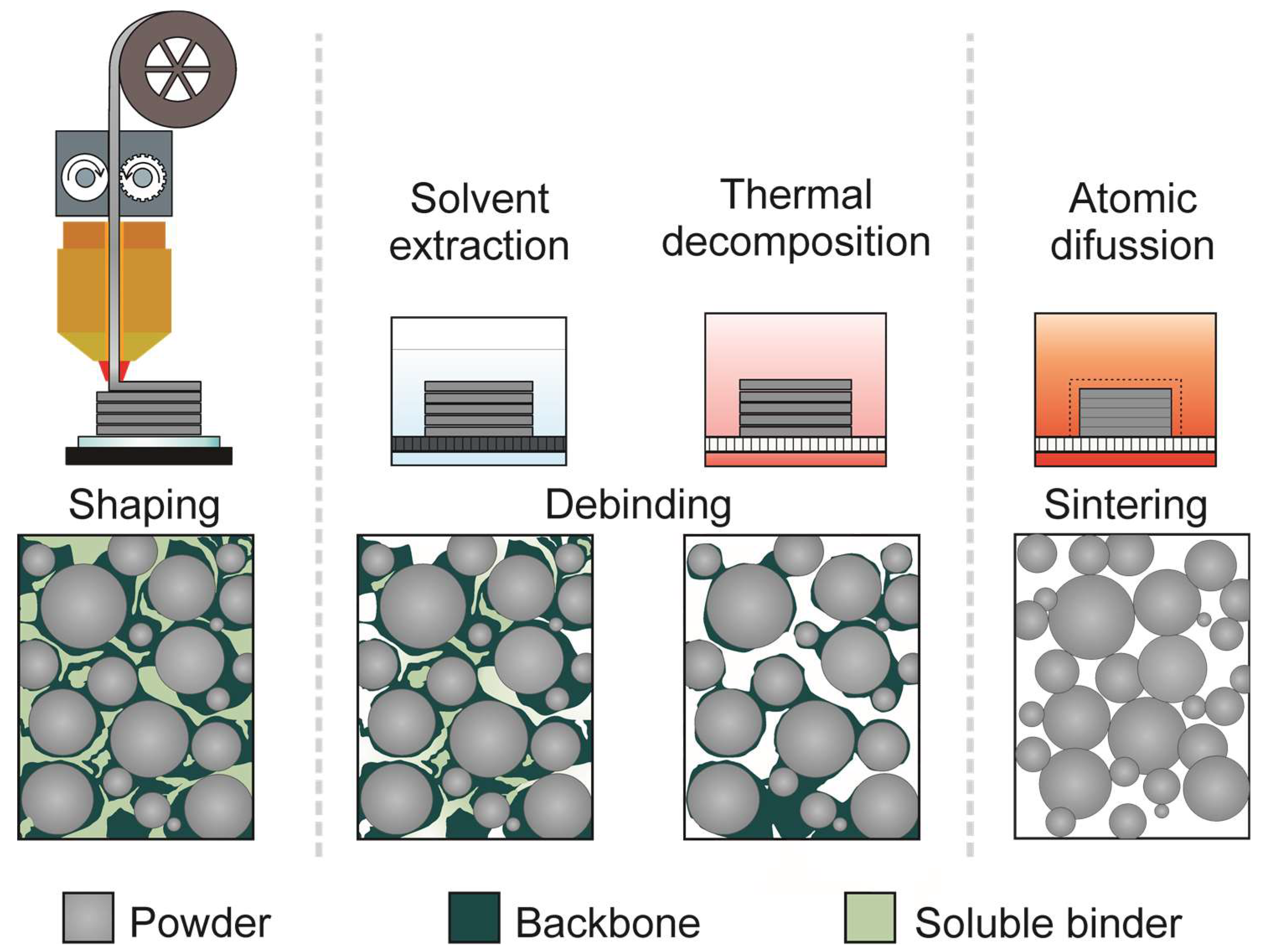

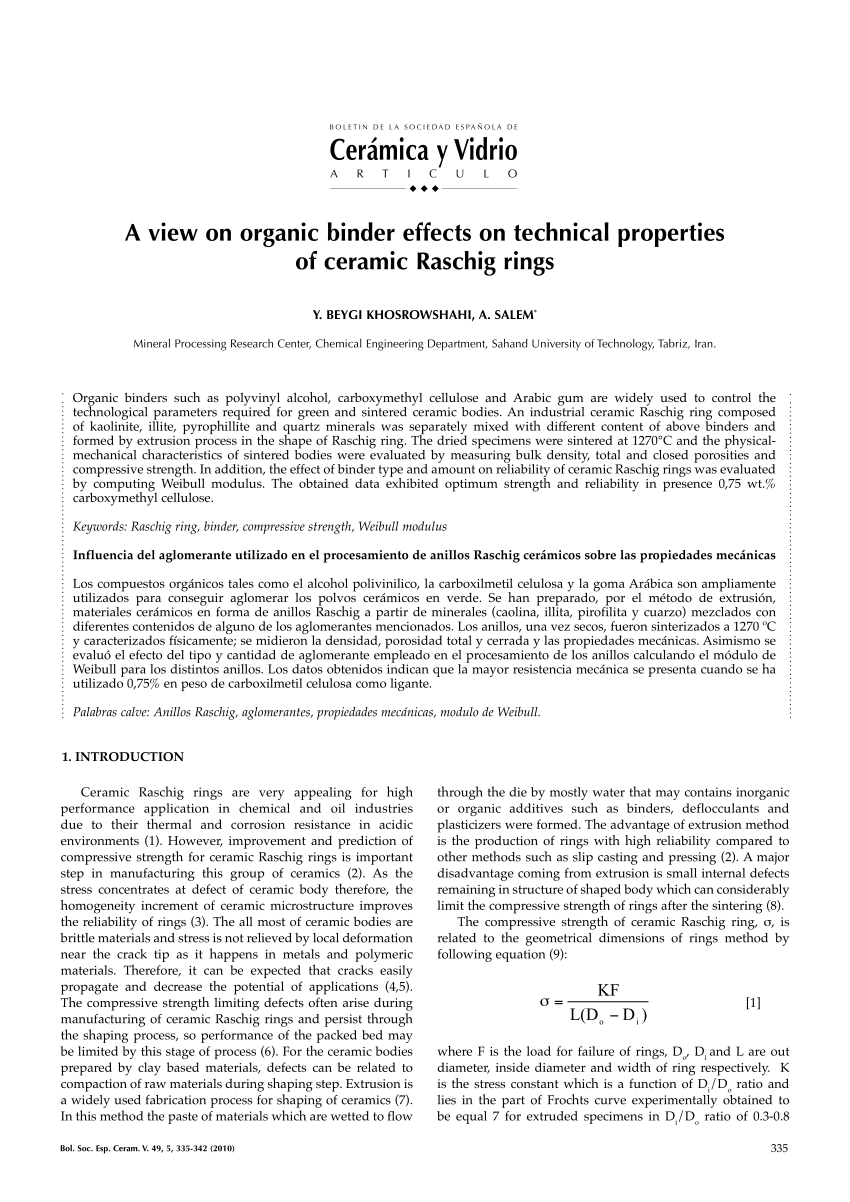

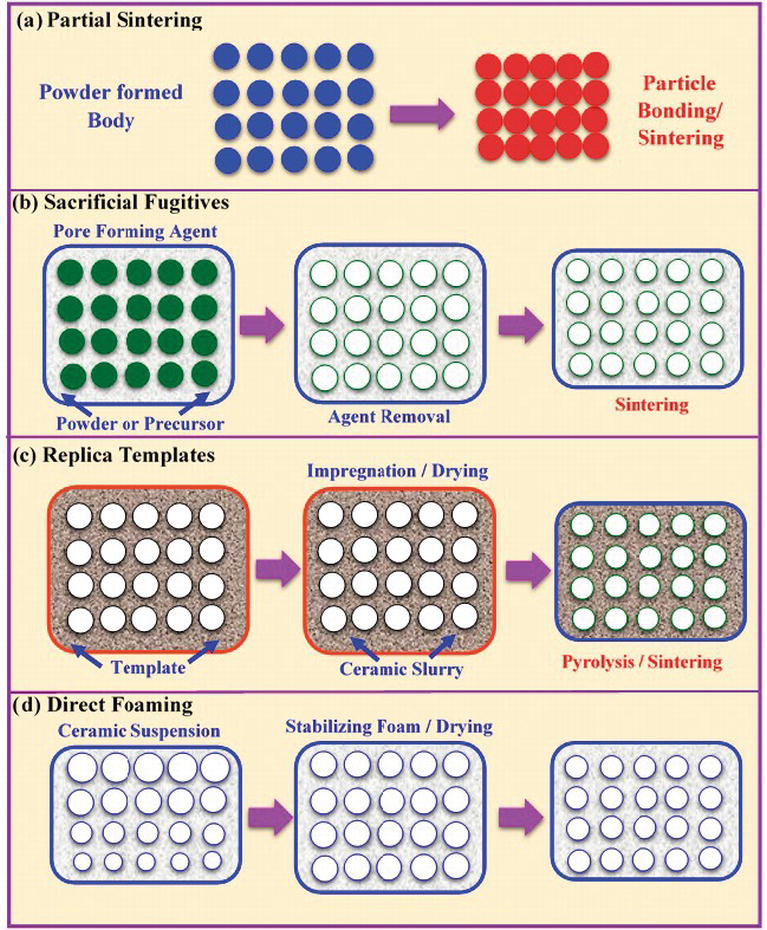

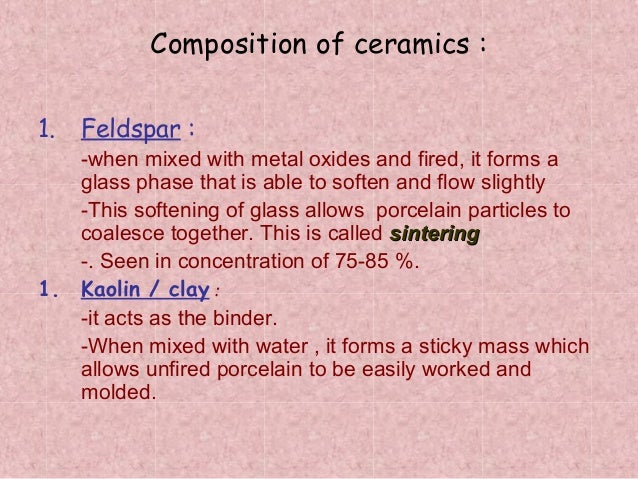

Ceramic slurry is obtained by mixing ceramic powder carrying vehicle binder and dispersant to produce uniformly dispersed ceramic slurry.

Ceramic binder composition. The ceramic binder compositions are solutions of at least one polymer at least one reactive monomer solvent and initiator. It is important to optimize the slurry composition in order to obtain high green density low green shrinkage and sufficient green strength to produce defect free demolding. A ceramic binder composition comprising. Binders for ceramic products are provided which are crosslinkable and impart improved tensile strength to ceramic green bodies.

The binders are particularly useful in tape casting processes for the manufacture of thin ceramic sheets which are used as substrates for electronic packaging. Used as a superior standalone system to rigidize refractory fiber shapes. Binders are substances that improve the mechanical strength of green ceramic bodies so they can pass through production steps before firing without breakage. Binders for ceramic bodies description.

And a binder comprising a polymer at least partially crosslinked with a crosslinking agent wherein the polymer is a copolymer produced from monomers comprising i vinylpyrrolidone and ii at least one monomer having a functionality selected from the group consisting of an amine an epoxide and combinations thereof. Ceramic binder compositions used in ceramic formulations for molding ceramic parts are disclosed. An overview of the major types of organic and inorganic binders used in various different ceramic industries.