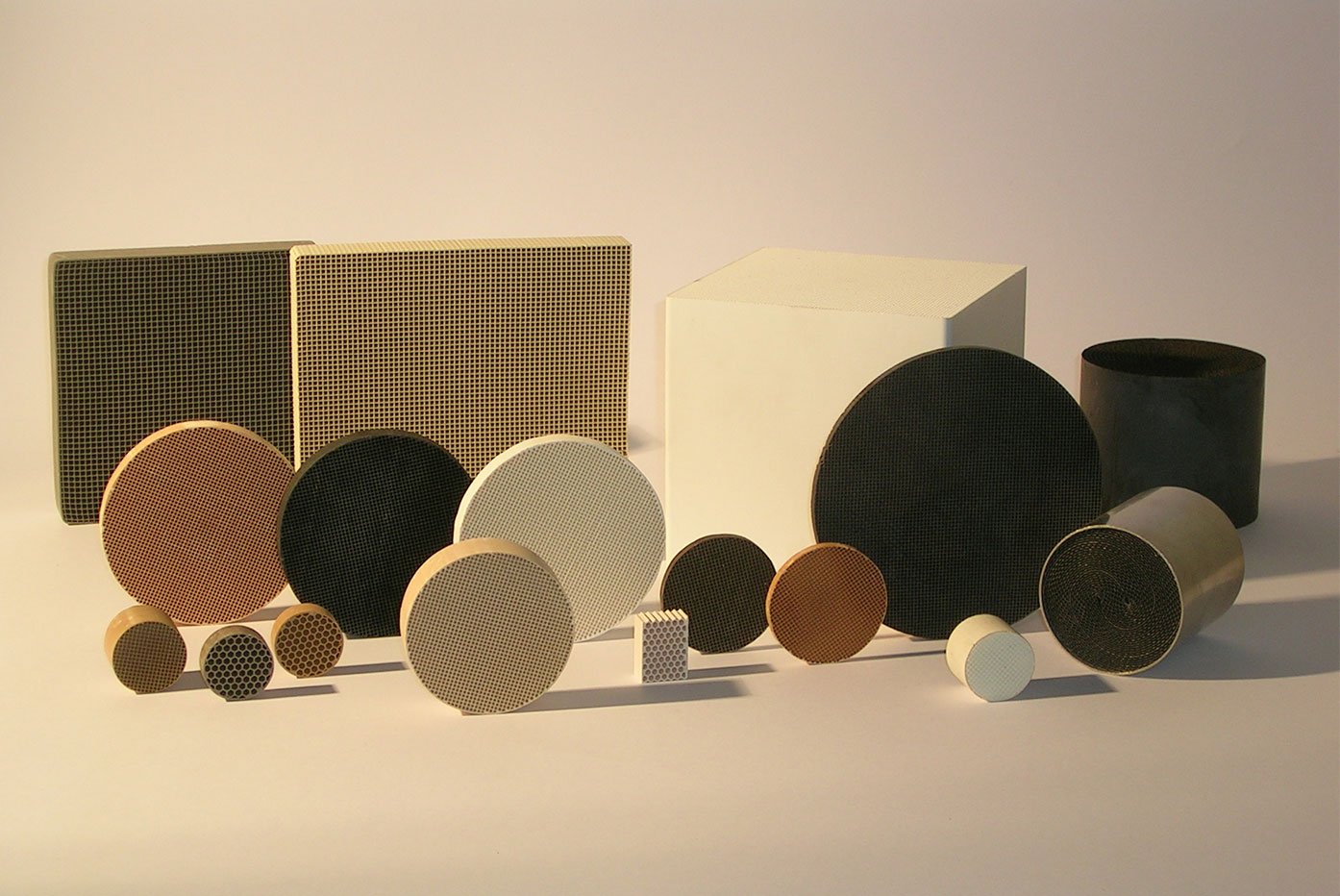

Ceramic Catalytic Converter Substrate Manufacturing Process

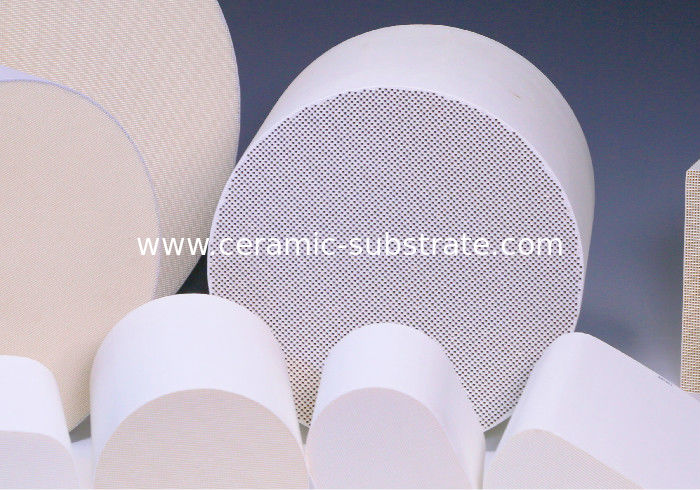

It offers a high surface area for washcoat deposit like al 2 o 3 and can be further impregnated with a catalytic component such as platinum.

Ceramic catalytic converter substrate manufacturing process. A manufacturing process for producing a particulate reactor substrate according to the invention includes the steps of first roll stamping small raised dimples into the fabric substrate to control its coiled density. Performance industries specializes in the manufacture of metal high performance catalytic converters and metallic substrates. The electrode is used to cut an extrusion die a feedhole is. The method of manufacturing the catalytic converter of claim 1 further described in that said ceramic material is from the group of gama alumina zirconia or zeolite.

The method of manufacturing the catalytic converter of claim 1 wherein said precious metal is from the group of platinum palladium or rhodium. Operating temperatures may be in excess of 900 and the substrate will also be exposed to fast moving corrosive exhaust gases rapid changes in temperature. Metallic cores offer a significant advantage being more economical and less restrictive than old ceramic cores while maintaining high durability. The substrate of a catalytic converter fulfils a vital role in supporting the catalytic material and at the same time must be capable of withstanding some extremely arduous conditions.

The ceramic monolith used in converters has a pore structure around 3 to 4 µm pores which allows both mechanical and chemical link to the washcoat.