Ceramic Coated Bearings Racing

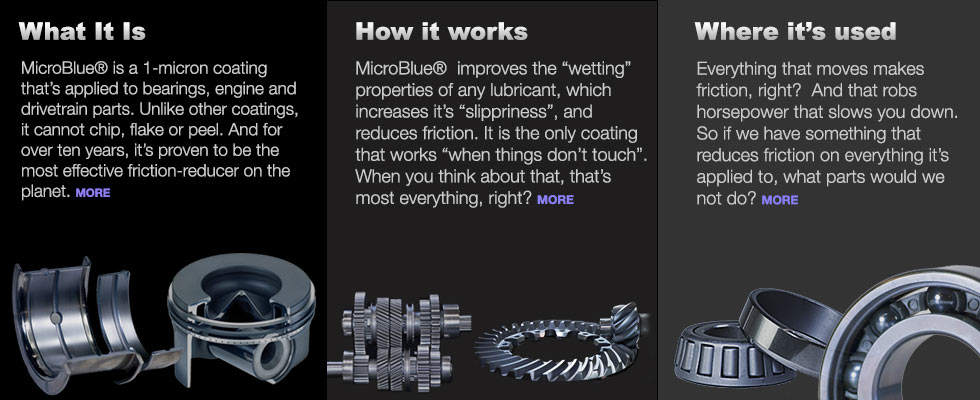

Building a coated bearing adds a number of extra steps to the process.

Ceramic coated bearings racing. They are self aligning to compensate for shaft misalignment and have end seals to keep lubricant in and dirt out. It has proven to protect bearings during metal to metal contact as well as from the erosive effects of cavitation. Anglia spindle bearings 03062 03162 07098 07204 150 00. We improve them by superfinishing the steel races then coat the races and the ceramic balls with microblue the coating that changes the way lubricants work.

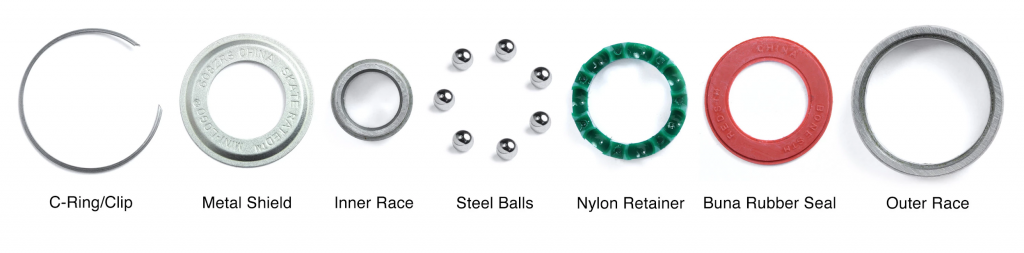

Ceramic bearings used in racing are constructed using conventional hardened steel races but with the steel balls replaced with ceramic balls. Wilson a veteran racer in his own right and an engineer and journeyman machinist by trade has spent years working to cure the ills of friction exemplified by steel bearings. Among the pioneers of ceramic bearing technology in auto racing has been arizona based performance bearing and its founder jack wilson. Not for use with ceramic coated aluminum or 300 series stainless steel shafts.

Our legendary ceramic nitride pro series silicon nitride differential balls and ceramic rc ball bearings stunned the rc racing scene with pure ceramic silicon nitride bearings not ceramic coated steel balls achieving a 79 weight savings and even greater durability hardness and smoothness than tungsten carbide balls. For technical drawings and 3 d models click on a. The ceramicspeed balls and steel races are matched to the micron after which each set of races is coated. A ceramic liner makes high speeds as well as rapid acceleration and deceleration possible.

King s pmaxkote is a new approach to coated bearings.