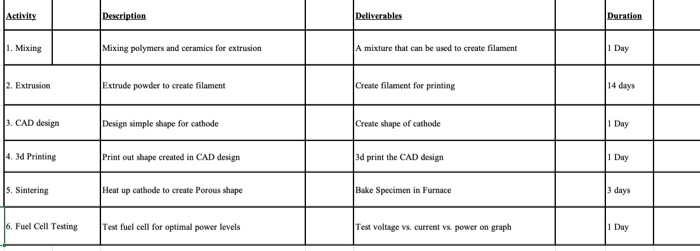

Ceramic Extruder Mixing Powder Polymer

Lucy clay lc disk 1 for czextruder pottery ceramic craft polymer clay fondant cake 9 disks for extruder.

Ceramic extruder mixing powder polymer. There are two types of extruders. In a simple compression process powder flows from a bin onto a two walled channel and is repeatedly compressed. The better the mix entering the screw the better the final mix. In the extrusion process highly viscous a plastic mix of ceramic powder with additives with a consistency that of potters clay is forced through a shaped die with high force.

Polymer melting and mixing 1. Sabu thomas in synthesis of inorganic nanomaterials 2018. They are available in a variety of sizes and have the ability to function with a large assortment of dies. Providing a better mix into the screw requires two things.

A mixing procedure that first uniformly disperses the additives through the base polymer s and secondly prevents them from segregating before or even as the mix enters the screw. Pottery techniques include the potter s wheel slipcasting and many others. Pixnor 20 pcs stainless steel green crowded mud machine polymer clay pixnor extruder craft gun cake fondant sculpture decorating tool set. Ajay vasudeo rane.

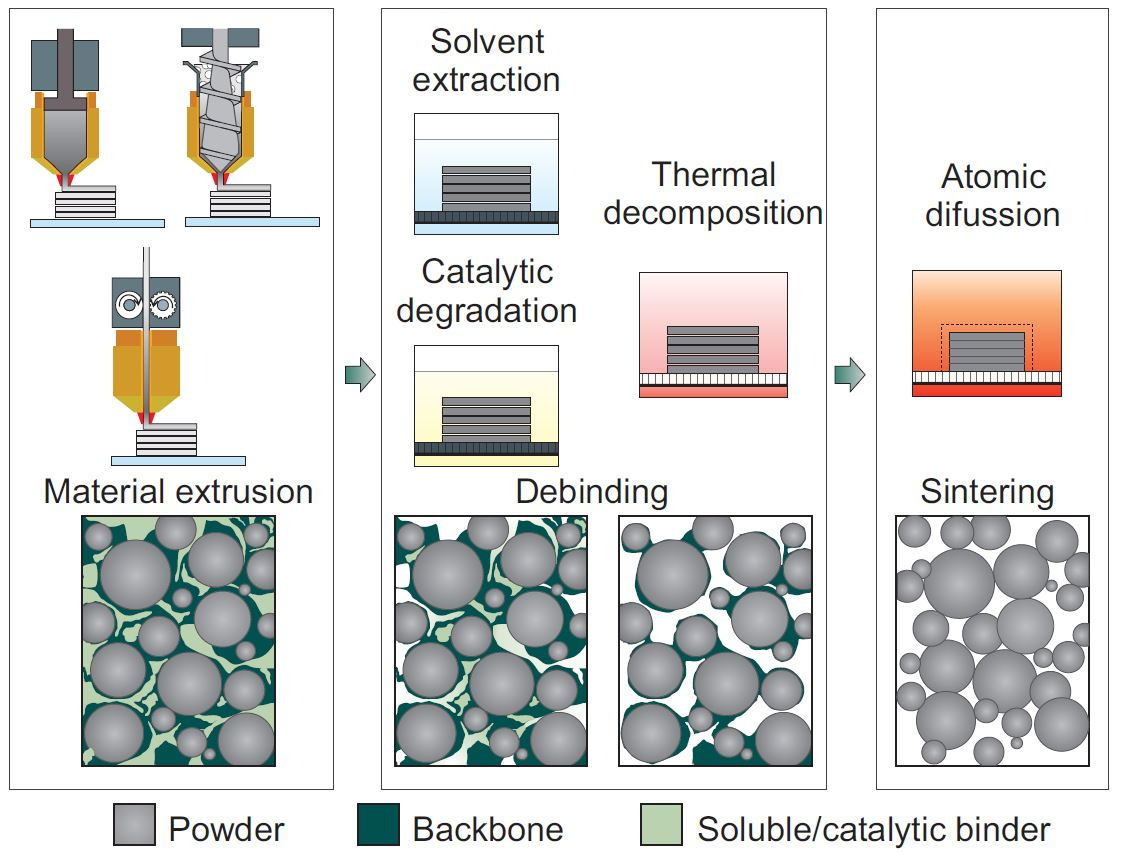

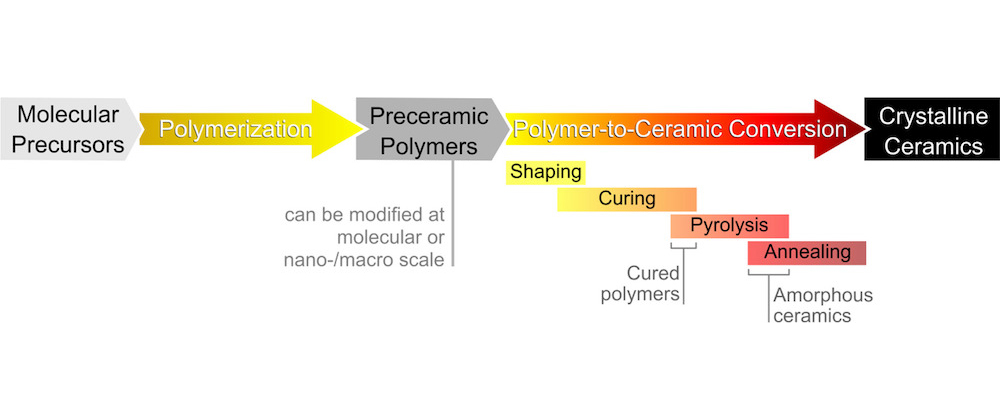

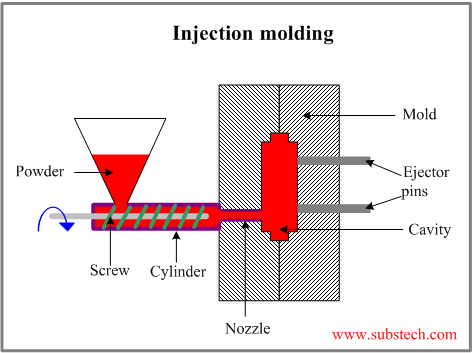

Cheremisinoff ph d in condensed encyclopedia of polymer engineering terms 2001. The process begins by making a mixture of a desired metal or ceramic powder with a binding agent such as a polymer wax or resin. We recommend using clay gun extruders for creating long coils for use in handbuilt projects and sculptures. To control and optimise the production it is interesting to model behaviour of the.

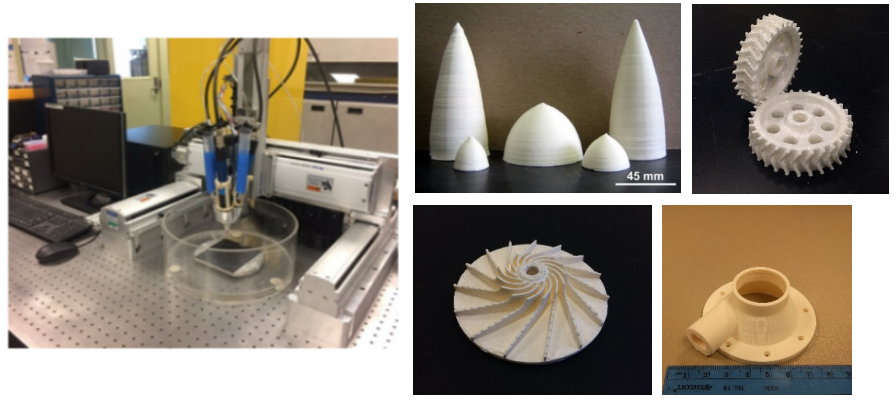

Scott creek clay gun extruders or the ceramic shop s extruder are durable easy to use and lightweight. This is similar to squeezing frosting out for cake decoration. There is a mixing principle in single screw extrusion that always holds true. Ceramic formulations metal or ceramic injection molding is a process used for forming intricate parts in a wide variety of alloys steels carbides and ceramic compounds.

The extrusion of ceramics often requires the wetting of the powder with a binder in order to produce a paste. Multiple screw extruders that is extruders with more than a single screw were developed largely as a compounding device for uniformly blending plasticizers fillers pigments stabilizers etc into the polymer subsequently the multiple screw extruders also found use in. Methods for forming powders of ceramic raw materials into complex shapes are desirable in many areas of technology.