Ceramic Failure Stress

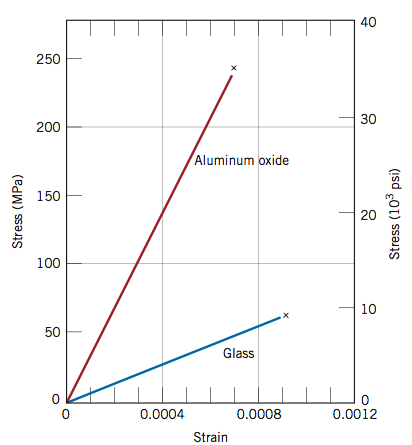

Failures in ceramic materials often occur when a tensile stress causes a fracture to propagate through the material.

Ceramic failure stress. Therefore a failure criterion has to be applied to predict the failure load from material data fig. They are strong when loaded in compression but weak when loaded in tension. Now let s look at a surface crack in a ceramic. Mohr s hypothesis for bi axial loading.

Bi axial failure criteria for different weibull parameters. Kingery ceramics division department of metallurgy massachusetts lnstihrte of technology cambridge massachusetts the sources and calculation of thermal stresses are considered together with the factors in volved in thermal stress resistance factors. So instead of the material blunting the surface crack as occurs in metals in a ceramic the stress from the crack ends up concentrated at the point of the crack. Multi axial loading there is a multi axial state of stress in many ceramic components.

Fracture surfaces contain important information about the cause of the fracture and. Properties affecting thermal stress resistance of. Obtained from uni axial tests. Factors affecting thermal stress resistance of ceramic materials by w.