Ceramic Firing Times

For this example we ll also see that the kiln will be down fired.

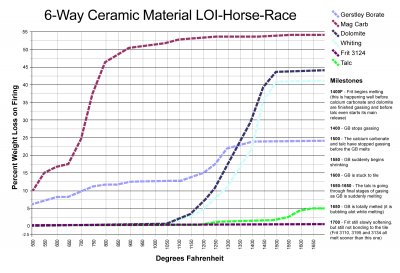

Ceramic firing times. When potters talk about ceramic firing ranges they are usually referring to the three most common. Kiln peephole the color of the kiln atmosphere. And if you re ready to get some real work done. The goal of bisque firing is to convert greenware to a durable semi vitrified porous stage where it can be safely handled during the glazing and decorating process.

Buyers may have just caught the ceramic bug and may have never heard of kiln wash or fully understand pyrometric cones. If you re looking for a medium sized high fire kiln we d recommend the evenheat hf 2318. Very low fire range. Firing converts ceramic work from weak clay into a strong durable crystalline glasslike form.

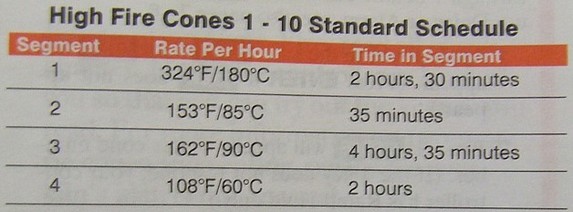

The purpose of this initial firing is to turn your pottery into ceramic material. Firing clay from mud to ceramic. The firing process is measured in cones a standard unit of measurement that accounts for time and temperature. Very low fire and lower mid range firing ranges.

Low fire mid range and high fire ranges. All of these kilns will reach at least cone 10 2350 f and will be perfect for your high firing kilns. The next step is to put the piece into the kiln for the first round of firing called a bisque firing. In regards to glazes we need to add two other ranges.

It is bisque fired and then glaze fired. Ceramic work is typically fired twice. Very low fire and lower mid range firing ranges. If you re looking for a small high fire kiln we d recommend the evenheat hf 1413.

Regular elements start to decay due to corrosion after 60 firings or so cone 6 10 and will introduce side effects such as longer firing cycle will effect glazes behavior and sagging kiln. Low fire mid range and high fire ranges. Often times buyers of these kilns are given very little information on how the kiln works or how to fire it. Regular elements for a busy kiln at medium to high firing range will increase your repair times repair cost reduce relays longevity and electric cost.

A cone 04 glaze firing schedule with down firing. When potters talk about ceramic firing ranges they are usually referring to the three most common. We offer a variety of high fire kilns at soul ceramics. In regards to glazes we need to add two other ranges.

A kiln temperature can be measured in three ways. Without the proper guidance firing pottery at home can have disastrous results. Because the bisque firing has already changed the clay into the ceramic material glaze firings can increase temperatures faster at the beginning and middle of the firing.