Ceramic Injection Molding Feedstock

Injection molding green body.

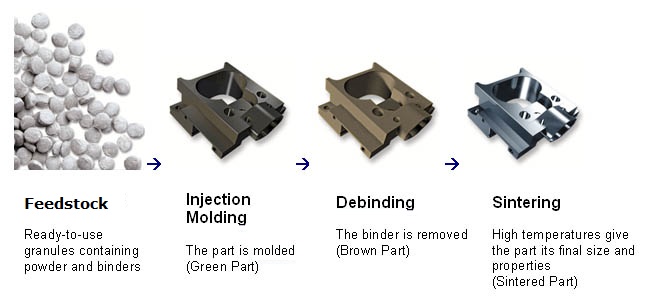

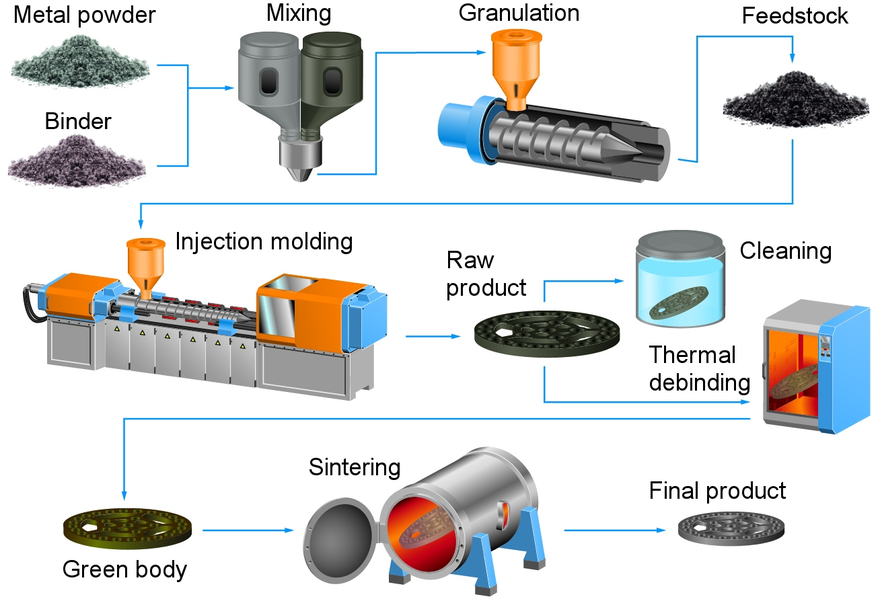

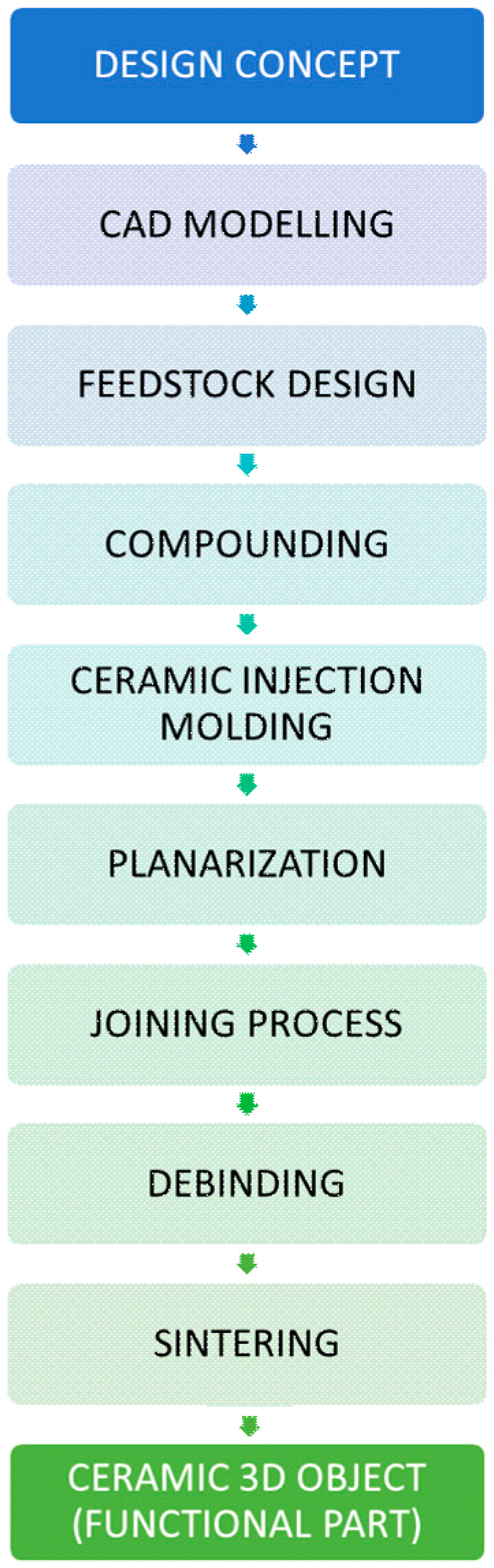

Ceramic injection molding feedstock. This ensures that the components made for our customers are of high quality and consistently reproducible in order to provide the finest parts at the very best price. This mixture is granulated to form feedstock feedstock is heated to form viscous slurry and injection molded to form green part. Feedstock preparation mixing the ceramic powder with binding agent 2. Thermal debinding ceramic injection molding cim feedstock based on nishimura s 30 years cim experience nishimura advanced ceramics produce unique and useful feedstock the thermal debinding ceramic injection molding cim feedstock compound.

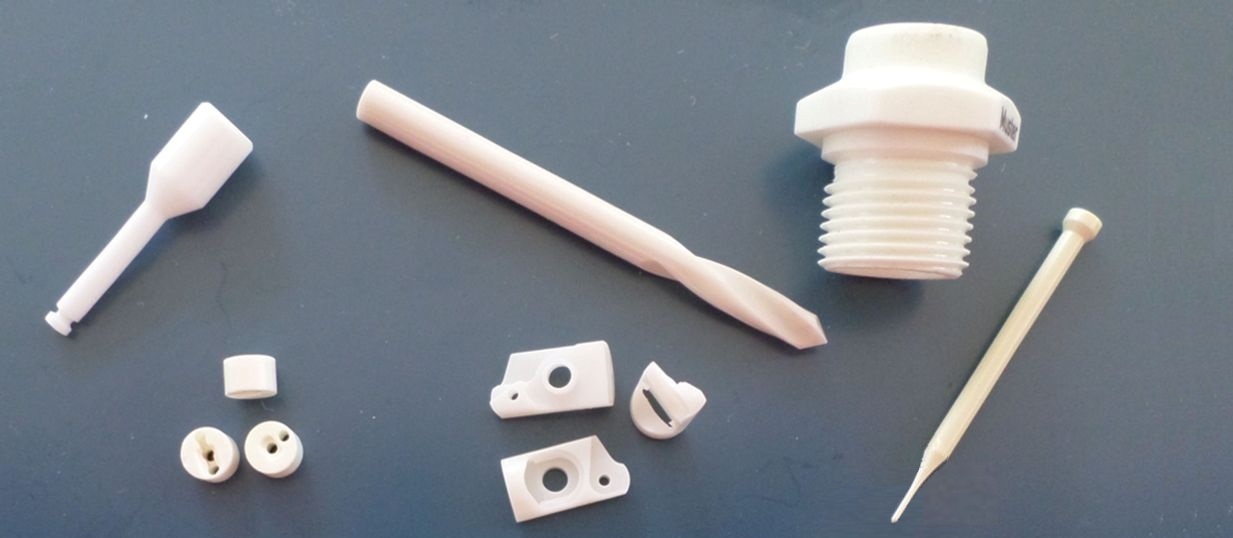

Ceramic injection molding technology. Fine metal or ceramic powder is mixed with a binder system into a feedstock and injected into a mold containing a microstructured mold insert. Ceramic parts molded from superior materials 1. How ceramic injection molding works fine ceramic powder is mixed with a polymer binder.

The ceramic injection molding process begins with very fine ceramic powders. Our comprehensive product line consists of metal and ceramic powders compounded with tailor made binding agents. Using sophisticated mixing technology the powders are compounded with thermoplastic binders to produce a homogeneous pelletised feedstock. During moulding the feedstock plasticizes and is injected with high pressure into the cavity.

We are proud of ourself as a pioneer of cim high pressure ceramic injection molding since we use cim technology from 1986. Catamold powder injection molding enables the economic production of geometrically sophisticated metallic components. Catamold powder injection molding is the leading ready to use feedstock for metal and ceramic injection molding. On sale from 2018 thank you for waiting long time.

Cim high pressure ceramic injection molding nishimura advanced ceramics produces 1 4 piece of small and complex shaped parts in one shot by cim high pressure ceramic injection molding technology. The technology consists of the following steps. The binder and the powder are combined in a variety of compounding equipment such as extruders and mixers. Ceramic injection moulding process after deciding which ceramic you want to have for your application the cim process is as follows.

This method is well established in replication by injection molding and metal injection molding mim or ceramic injection molding cim. At wunder mold we use only high quality powders and organic constituents in our injection molding feedstocks.