Ceramic Membranes Price

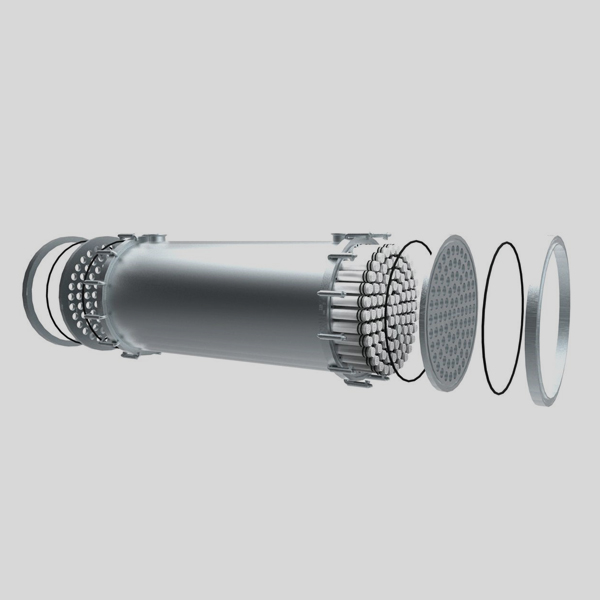

Membralox ceramic membranes comprise a highly controlled surface membrane layer that is formed on the inner feed side surface of a more open support layer.

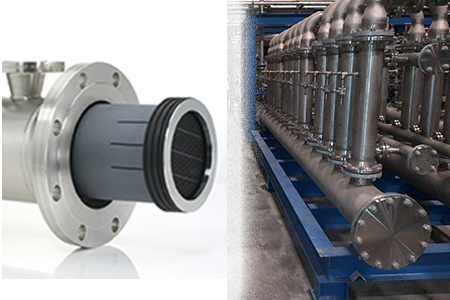

Ceramic membranes price. Tang in membrane based salinity gradient processes for water treatment and power generation 2018. Three different types of materials are available ultrapure µalumina zirconia and titania. So the membrane replacement component of the opex is then approximately proportional to the ratio of the membrane cost l to the net flux j times the membrane life t. By contrast with polymeric membranes they can be used in separations where aggressive media acids strong solvents are present.

This book is a single authored guide to the developing area of ceramic membranes. Ceramic membranes normally have with an asymmetrical structure with porous support active membrane layer the macro porous support ensures the mechanical resistance while the active layer. Opex l j t this means that as far as the cost effectiveness of the ceramic membrane compared with the polymeric one is concerned the determining factor is the ratio of the term l j t for the two materials. It starts by documenting established procedures of ceramic membrane preparation and characterization.

Most ceramic membranes are made of alumina titania silica zirconia or mixture of these materials 93 the basic structure of ceramic membranes consists of a macroporous support layer and meso or microporous active layer. They are used in membrane operations for liquid filtration. Ceramic membrane ask price. Ceramic membranes are a type of artificial membranes made from inorganic materials such as alumina titania zirconia oxides silicon carbide or some glassy materials.