Ceramic Pro Failure

Machine failure due to dust and grime build up short circuits on electrical installations labour and water saving on cleaning and maintenance loss of efficiency on solar panels due to reflection from unclean surfaces and many more wear and tear scenarios.

Ceramic pro failure. Ceramic pro offers a complete line of surface protection products. We offer a range of ceramic coating and paint protection film products each formulated for specific surfaces. The failure of ceramic materials is characterised by low toughness which leads to brittle fracture without preceding plastic deformation subcritical crack extension and large scatter in the mechanical properties. The coating formulas are molecularly designed for surfaces such.

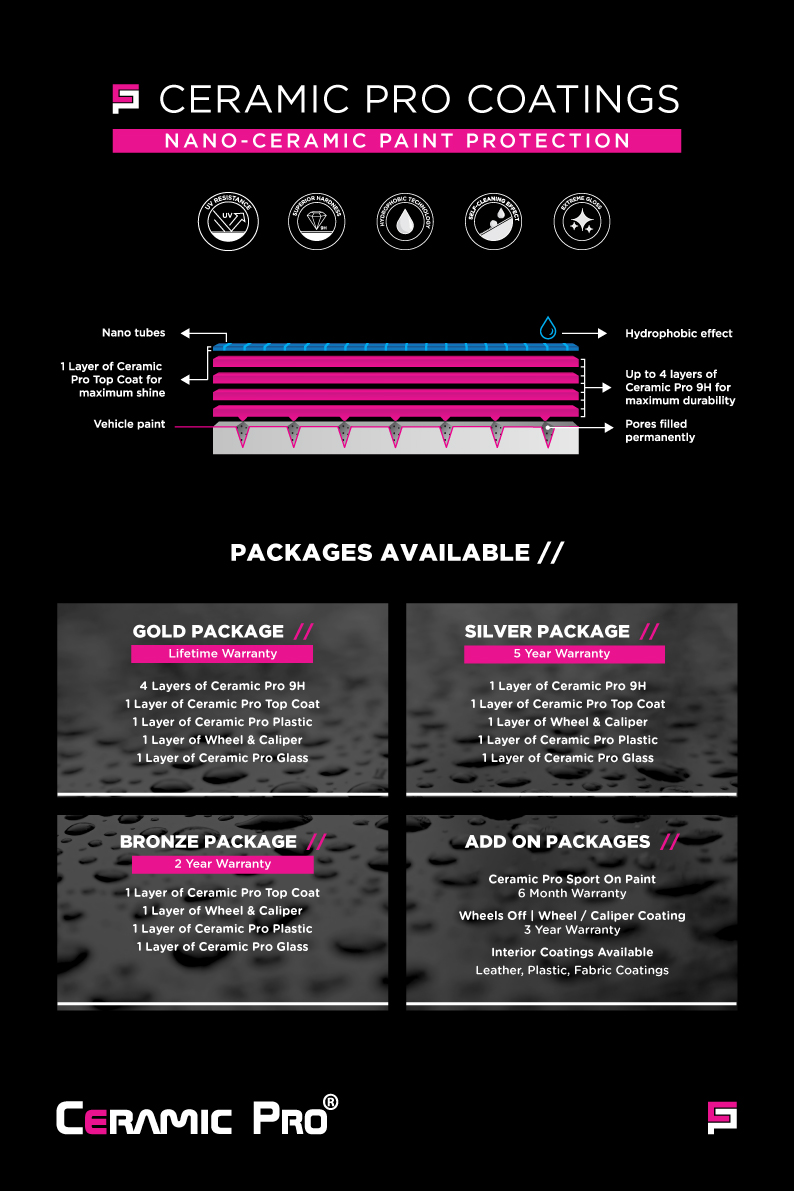

An innovative solution for surface protection in automotive marine aircraft construction machinery and textile industries. Ceramic pro is a nanoceramic protection system of the new generation. Ceramic pro protects on an industrial level to prevent. Our coating and film protection offerings are based on proven nano ceramic technologies.

We discussed this earlier. Another way at looking at resistance to failure for ceramic materials is to examine the energy required to drive cracks through the system. As an example the lifetime. In other words we have a coating formula or paint protection film.

Generally a ceramic with more defects is weaker. Click the resistance to fracture or area under the stress strain curve is the called the toughness. Our ceramic coatings and ppf are designed for automotive marine aviation and industrial applications. It is based on a unique formula of ceramic molecular compounds.