Ceramic Engine Valves

Here is an article on the prospects for an adiabatic turbo diesel from 1987 adiabatic diesel engine technology in future transportation.

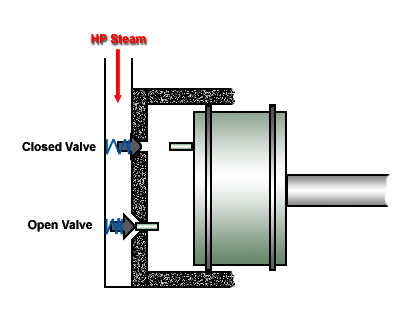

Ceramic engine valves. Powerkote cbx ceramic thermal barrier coating. Thermal barrier coating designed for performance engines running. We do this by the application of a dry film lubricant. Ceramic and ceramic head valves have been demonstrated for use as exhaust valves at only 40 percent the mass of steel valves but the brittle failure mode of ceramic versions can have devastating consequences on the engine.

The engine was built from a new bare gm performance parts ls2 engine block to take advantage of its larger 4 00 inch bore but the rest of the external dress was standard camaro ls1. Xeramic ceramic engine protector 20103 20103 1 high quality engine treatment for 50 000km optimal protection even after chaning the engine oil. Creates a hard surface specifically designed for engines running high volumes of fuel and or high compression ratios or closed chamber heads. Such as piston rings bearing valve lifters etc.

The japanese concern touts the environmental advantages of its ceramic auto components which include exhaust control valves diesel fuel injection components and gas turbine components. This reduces the friction particularly in engines where oil flow is restricted to the head. Intake valves usually do not suffer as severely as exhaust valves which see combustion chamber temperatures. Jacers is a leading source for top quality basic science research and modeling spanning the diverse field of ceramic and glass materials science.

Due to the thermal insulating properties you can also find ceramic coatings in engine areas that need to withstand high heat like pistons or exhaust headers but this is. Therefore the primary concern is lubricating the valve stem and seat. For all other applications use cbc2 above. Herbert gasthuber roland krebser using ceramics for mass reduction in valve train 4th international symposium on ceramic materials and components for engines 10 1007 978 94 011 2882 7 1059 1066 1992.

Ceramics are used in engine applications where there isn t any impact or tension loading ceramic ball bearings turbos are a good example as well as valves cams etc. Current trends in spark ignition engines are toward multivalve engines capable of operating at relatively high speeds to maximize performance and fuel economy at acceptable emissions levels.